MAIN AND AUX SYSTEMS

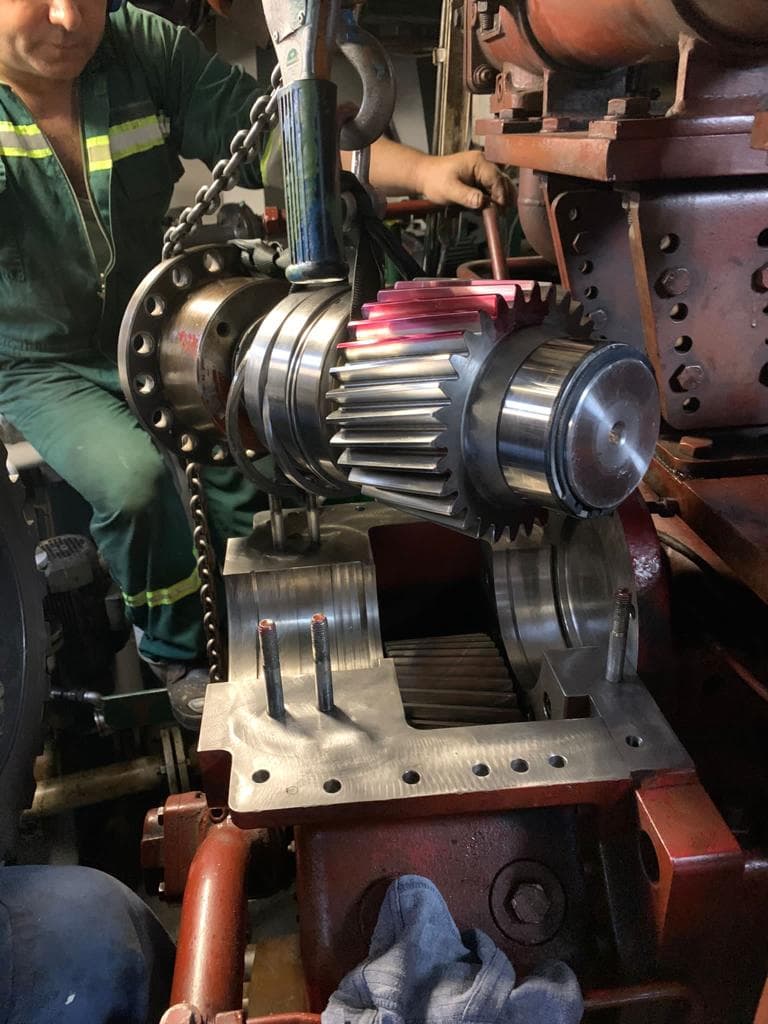

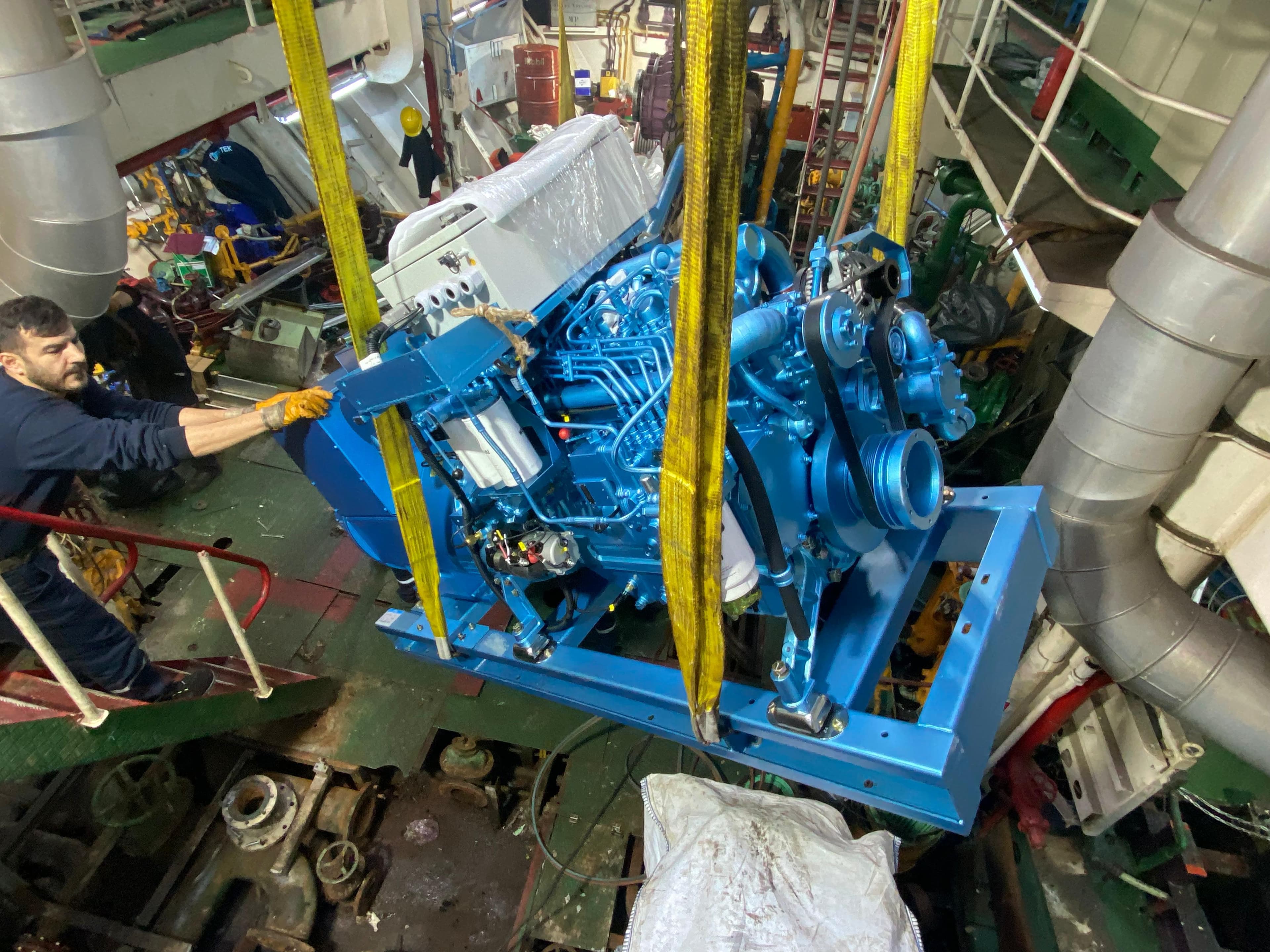

RMS Ship Repair provides comprehensive Main and Auxiliary Systems Repair and Maintenance services, covering on-board overhauls, inspections, and performance evaluations as well as full workshop and reconditioning capabilities. From main and auxiliary engine routine and major overhauls to bearing inspections, crankshaft works, fuel injection refurbishment, precision machining, and component reconditioning, all services are executed by experienced in-house engineers. With both on-site and workshop based support, RMS ensures reliable engine performance, extended component life, and full compliance with class and operational requirements.

MAIN AND AUX SYSTEMS REPAIR AND MAINTENANCE

• Main Engine Routine / Major Overhauling

• Auxiliary Engine Routine / Major Overhauling

• Bearing Inspections (Main, Crosshead, Crankpin, Camshaft, Thrust Bearings)

• Main Air Starting Valve Overhauling

• Engine Tie-Rod / Foundation Bolt Check and Re-Tightening, Troubleshooting

• Supervision Works

• Engine Performance Evaluation

• Cylinder Condition Evaluation

• Chain Drive Inspection

• Camshaft Inspection

• Crankcase Inspection

• Moment Compensator Inspection

• Crankshaft Replacement

Workshop Services

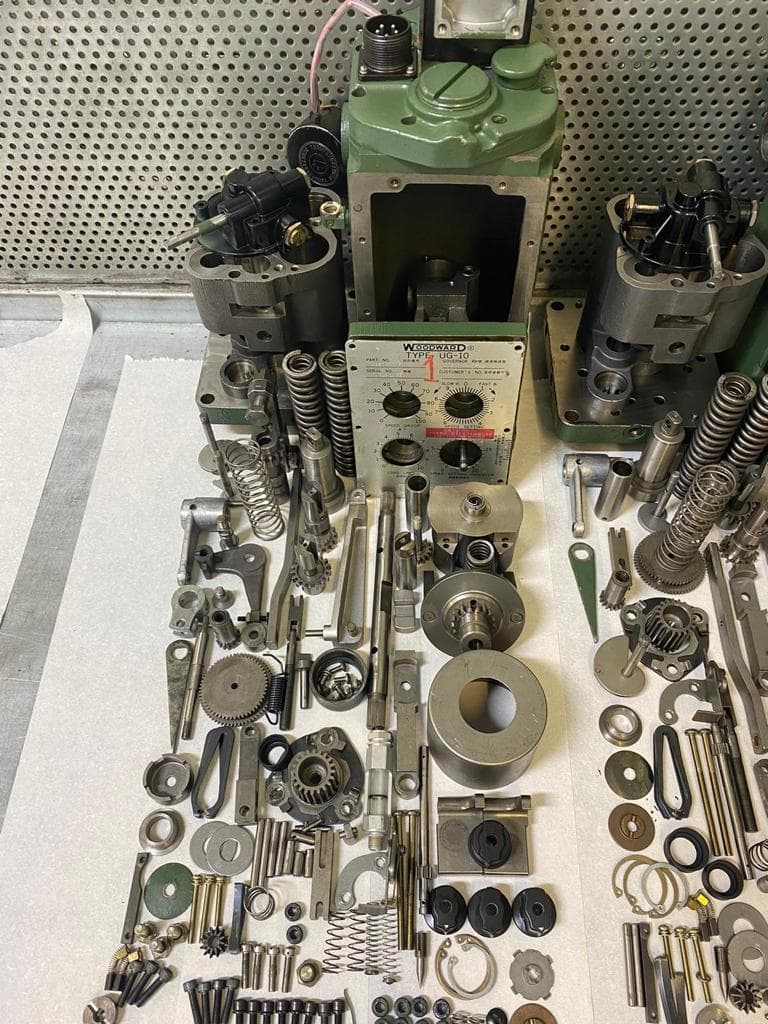

• Fuel Injection Valve Refurbishment

• Fuel Pump Overhauling

• Engine Units (Cylinder Head, Piston, Liner) Overhauling

• Cylinder Liner Honing (up to Ø700mm)

• Air Starter Overhauling

• Auxiliary Pumps Overhauling

• Machining & Grinding Works

• Special Fabrication of Parts (Pin, Shaft, Bush, Gear, Impeller, etc.)

• Chemical & Ultrasonic Cleaning of Coolers

Workshop Reconditioning

• Piston Crown Reconditioning

• Piston Skirt Reconditioning

• Cylinder Head Reconditioning

• Valve Spindle Reconditioning

• Valve Seat Reconditioning